Rotary 4th/Fourth Axis® Inside Ring Engrave Option

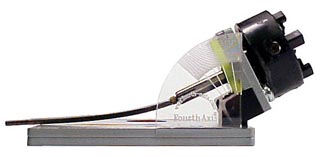

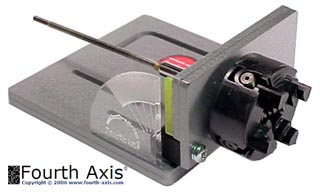

The Fourth Axis®IREO™15 & IREO™20 has a 45° tilt stage

Optional for the Fourth Axis®15 & 20 is a tilt stage with flexible drive, which accepts the regular faceplates and chuck, then tilts them to your selected angle. An engraving tool then can reach the inside surface of a ring, for true rotary inside engraving. Remember the movie Lord of The Rings? You too can engrave the finished wax before casting. Unlike faint laser engraving, true rotary engraving may be as deep as you choose with the Fourth Axis®IREO™15 & IREO™20.

Unlike laser work or diamond-drag scribing of finished rings, Inside Ring Engrave Option™15 & 20 used at the wax stage, does not destroy electroplated ring surfaces, nor leave any sharp edges.

Fourth Axis® provides tables of maximum engraved depth for each ring width, plus the angle setting required. Angle setup is via the finely calibrated quadrant protractor with screw locking. This featured option for the Fourth Axis®15 & 20 is NOT available for the PIX-30.

Description

Internally lubricated, torsionally symmetrical, our

steel drive shaft directly couples the IREO.

Fourth Axis®IREO™15 & IREO™20 are optional extensions for the Fourth Axis®15 & 20 rotary micromachines. Intended for engraving inside wax ring masters, the IREO™15 and IREO™20 expose the inner surface of a wax ring tube to the engraving toolbit.

IREO™ uses a tilting stage and flexible drive shaft to provide toolbit access while the IREO™ is driven by the Fourth Axis®15 & 20. Twin flanged ball bearing units provide smooth rotation of the finely ground spindle. Four compression fingers grip the square-ended flexible drive shaft.

Our 4-jaw independent chuck allows easy adaption to hold almost any size of wax tube or model for inside-surface engraving. The jaws are reversible and a hex key is supplied for adjustment.

The tilting stage angle is read from a laser-calibrated protractor, marked in single-degree steps. Angle adjustment is controlled by a stainless steel socket-head screw (key supplied) which locks a heavy-duty pivot hinge with 8mm shaft.

Positioning

The two sizes of IREO™ have different mounting bases, because the worktables of MDX-15 and MDX-20 are different. The MDX-20 has a ';swimming pool' in which we locate the IREO™20. The MDX-15 has a flat top table on which the IREO™15 locates with twin rails, front and back. The "swimming pool" prevents IREO™20 moving front/back. The twin rails prevent the IREO™15 moving front/back.

IREO™15 and IREO™20 are held down by strong neodymium magnets in their mounting bases.

Both types can be adjusted left/right by sliding, then screw-clamping in the desired location. The IREO™20 includes automatic alignment underneath 'top dead center', by an M4 screw which locates in a threaded hole in the chassis of the MDX-20. Because the MDX-15 does not provide access to such a hole, IREO™15 is screw-clamped against left/right motion into the M3 threaded hole at right-rear of the MDX-15 motion table.

Techniques

For very narrow rings and very large diameter rings, only a small tilt angle is required. It is possible to ignore this angle, if the engraving depth is large, but in most cases, it is advisable to project 3D text onto a ramp whose angle is the same as the tilting stage angle. If you draw text rotated 90° to occupy 76.75mm text length on the Y-axis, also making the desired text height less than the ring width on the X-axis, everything will fit perfectly in one revolution.

Everybody uses different software, but you may find it useful to draw the ramp surface with the same angle as the tilt stage, project your text onto the ramp, then delete the ramp before making CNC code.

Notes on design philosophy

Fourth Axis®15 & 20 rotary micromachines cleverly place the center height halfway up the Z-stroke. This allows full diametral penetration when scanning. Our IREO™15 and IREO™20 continue the same philosophy, maintaining the 30mm center height. When you tilt the IREO™ stage, it needs a flexible shaft to follow a 'J' curve to the 4-jaw driving chuck.

We terminate the drive shaft in a square shape for perfect fixing in the driving chuck and gripping in the stainless steel compression fingers of the IREO™. Height and workspace intrusion calculations can be made using the angle displayed on the inbuilt acrylic protractor. Use our IREO Calculator to relate protractor angle with tool shank size, ring inside-diameter, and ring width.