Using Fourth Axis® magnetic faceplates

- in batch production, to minimise tool changes and recalibrations:

In processes involving multiple tools or multiple passes, the master and slave quick-change magnetic faceplates are beneficial. You can set the first tool, run a batch of parts mounted to a batch of slave faceplates past it, then set the subsequent tool(s) and run the same batch of parts. This minimises changeover times and eliminates recalibration procedures. The precision with which the faceplates locate on the three drive studs and against the magnetic surface is amazing.

- in critical work needing off-machine inspection prior to subsequent passes:

Manual inspection of the work mid-process or between tool changes is now possible with the use of the faceplates -- your material can be removed from the machine, inspected, cleaned, photographed etc, yet the work will reset into precisely the same location.

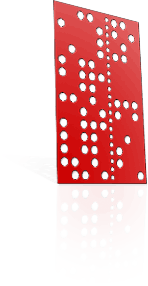

Pictured: Fourth Axis magnetic slave plate (left) and master drive plate (right)

The master drive plate provides three equi-spaced drive bosses which seat in conical recesses in the slave plates. Three magnets in the master provide axial attachment to three perfectly matched magnets in the slave. The faceplates are made from readily drilled (yet rigid) acrylic.

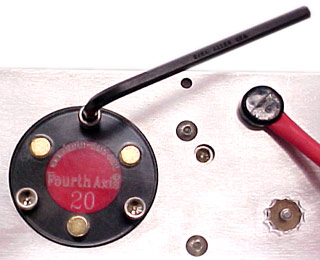

Magnetic faceplate kit and scan target

This kit includes:

- 1 master drive plate

- 2 slave plates

- three driving socket-head cap screws

- hex key for driving screws

(scan target for illustration purposes only)

3 x #8-32 screws homed through master plate into spindle face

The three drive screws are 10mm thread-length stainless steel socket-head cap screws. Take care not to over-tighten them.

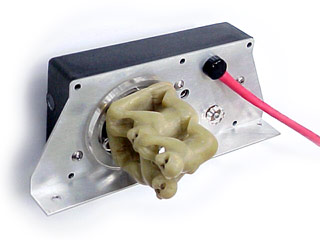

Scan target is double-face taped to correct surface of a slave plate

Always attach your scanning or milling target to the right-reading side of the slave plate. You may use double sided tape, any suitable adhesive, or a countersunk head screw (metal thread or self-tapper as appropriate for the target).

Master and slave plates interlock concentrically at correct rotation

The precision with which we manufacture this system is critical. The correct orientation is necessary for proper engagement. Repeatability is ensured when you match the "Fourth Axis" engraving in the master and slave plates.

A regular/flat screwdriver is used to disengage a slave plate

Gently lever the slave plate straight off the master drive plate. Once the magnetic bond is broken, the slave is readily removed, to check, measure, exchange or photograph targets.